Sometimes a newbuild comes along and, for whatever reason, is placed in reserve as a future subject for this monthly article rather than feature at the time. This month’s vessel is just one such example as in-depth information and diagrams were not readily obtainable when the subject’s delivery was announced.

Following in the Wake of the Dokter

The Dutch island of Texel (pronounced Tessel) is a municipality with a population in excess of 13,000. Located in the province of North Holland in the Netherlands, it is the largest and most populated island of the West Frisian Islands in the Wadden Sea and is situated north of Den Helder.

The ferry operator Royal TESO N.V. provides the only public service to and from Texel. TESO is an abbreviation for Texels Eigen Stoomboot Onderneming, translating as Texel’s Own Steamboat Company. Following dissatisfaction with the previous ferry service, Islanders formed an association in 1907 (TESO), led by local physician Adriaan Wagemaker, to operate a chartered ferry of their own. In 1908 the association was changed into a public company and Islanders raised 75,000 guilders to build their first vessel, which entered service in August 1908. TESO celebrated its centenary in 2007 and was awarded the “Royal” prefix to its name by Queen Beatrix. The route served between Den Helder and Texel crosses the deeptide race of Marsdiep, and is 4.2km in distance with a crossing time of 20 minutes.

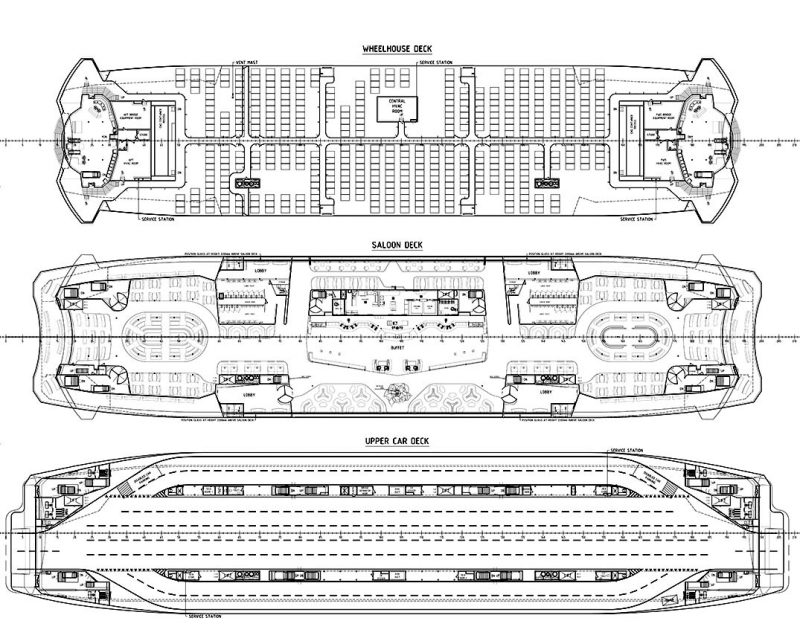

Quality and reliability are key factors for the ongoing success of the ferry operation so modern, well maintained ships are essential. To conserve this service record, TESO invests in the tonnage approximately every 12.5 years and a new vessel replaces the oldest ferry on the route. An increase in capacity of 10% is automatically factored into the new design so as to counteract increased waiting times at each port. The onshore mooring facilities, owned by Rijkswaterstaat, were only part way through their operational life of 50 years when the newbuild was drawn up in 2012 so a larger ferry could not be wider or longer. C-Job Naval Architects had been invited to the TESO newbuilding team with an improved/ enlarged version of the existing 13,256gt/2005 built ferry Dokter Wagemaker being sought. The Vripack design office became involved in the project in May 2013 and was awarded the task of exterior styling and interior design. Various standard options to increase car capacity were explored but disregarded until the solution was arrived at where the upper car deck and passenger lounge were widened beyond the main hull profile, resulting in the desired increase in capacity. The two additional car lanes that resulted, along with an increase in the overall length by 5.00m, gave a capacity increase of 60 cars (380 total) compared to the 320 car capacity of the Dokter Wagemaker. This design provided the newbuild, to be named Texelstroom (which translates as Texelflow), with an unusual but highly functional profile. The new vessel’s sustainability, environmental impact and efficiency were also placed under scrutiny, as with most new passenger ships that make it to the drawing board in this day and age. The Texelstroom’s overall length is 135.40m which accompanies a varied beam of 23.00m (hull) and 27.90m (maximum). The design draught is 4.050m with a maximum draught of 4.40m when laden. The hull depth to the main deck is 7.18m and the ship has a gross tonnage of 15,483gt. Potential fuel savings and any reduction in exhaust emissions were high on the list of priorities. The hull form has been hydrodynamically-optimised to reduce drag, heat recovery is harnessed and all lighting is provided via over 2,400 LED installations. LaNaval Shipyard in Sestao on the Bilbao Estuary, Spain, was awarded the construction contract for the Texelstroom in May 2014. This facility has been in operation for over 100 years and, since 2006, is 100% privately owned. The principal shareholders are industrial companies involved in the shipbuilding and shipping business.

The yard has built a variety of tonnage including Shuttle Tankers, Oil and Product Tankers, Chemical Tankers, LNG Tankers, Suction Dredgers, custom built vessels for the Offshore Oil & Gas, Offshore Wind plus Ro-Pax ferries. The keel of Yard No. 344 (Texelstroom) was laid on 30th December 2014. The launch ceremony followed on 30th July 2015 and commenced with an “Aurresku”, a typical Basque dance in honour of the godmother. Among the guests was TESO’s Managing Director, Mr, Cees de Waal and his wife, Kiran De Waal-Sukhai, who acted as the Texelstroom’s godmother, as well as other institutional and shipbuilding representatives. The vessel was towed across the River Nervion to a dry dock at Santurzi on 26th February 2016 and then onwards to Santander.

Pressurised Hybrid

During the initial design, the use of both LNG and CNG as fuel was examined with the decision being made to select a Dual Fuel System using CNG (Compressed Natural Gas).

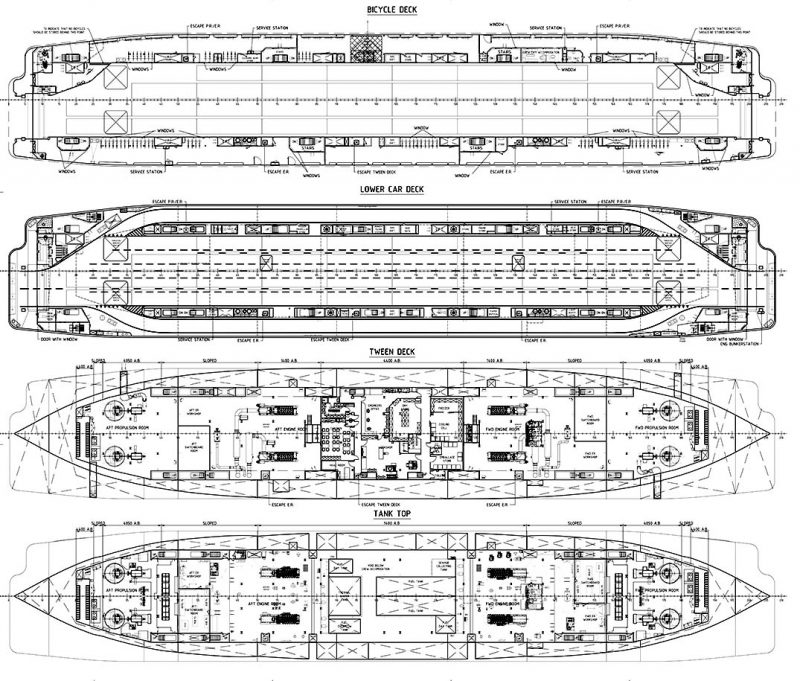

Furthermore a hybrid propulsion system was incorporated, with battery packs, to reduce the peaks in onboard energy demand. The use of LNG was ruled out because of the lack of infrastructure and the higher costs and logistical challenges of direct supply by road tanker or bunker barge. At an evidently cheaper cost per megawatt of power than either diesel or LNG, CNG was chosen as the fuel form. By coupling to a compressor station ashore near the ferry berth in Texel, with a connection to the Dutch gas network, CNG is delivered at night to the banks of CNG cylinders aboard the ferry. The cylinders are refilled to a pressure of 200bar. It is estimated that one bank of cylinders is sufficient for almost a whole day’s operation. It is planned that the vessel will sail on CNG as much as possible, and with abundant installed power under normal conditions using only the dual fuel engines, the Texelstroom will meet maximum service speed requirements as and when necessary. The CNG cylinders are located in a recess aft of each wheelhouse. The dual fuel engines are started in the diesel mode, but change over to dual fuel after a couple of minutes. A mixture of air and gas is injected into the cylinders and this is then compressed and a small pilot injection of diesel produces the ignition. The vessel operates from 0600-2200 daily on an hourly rotation. The engines installed in the ship are two 2,131kW/750rpm Anglo Belgian Corporation 12DZC MDO (marine diesel oil/low suphur bio diesel) engines located in the forward engine room and two 2,081kW/1000rpm Anglo Belgian Corporation 12DZD dual fuel CNG/MDO engines in the aft engine room. These units drive four 1,800kW Rolls Royce US 255P30 fixed pitch Azimuth Thrusters, two at either end of the vessel. The service speed provided is 10 knots (in economy mode) or a top speed of 15.40 knots.

Sufficient power is available to ensure normal service is maintained in at least winds of Beaufort force 9. As mentioned above, the advanced energy management system on board also utilises 252 Corvus Energy AT6500 48V lithium ion modules. The 1.6MWh battery capacity is used to increase efficiency and for backup power. Class approved by Lloyd’s Register, the Corvus Energy system is the only Type Approved ESS for marine vessels in the market today. Corvus Energy technology is an effective solution for hybridisation of commercial CNG powered vessels. The consistent power and reliability provided by the ESS supports the specific performance attributes of these clean vessels. The batteries are located in a dedicated facility behind the propulsion room. They can be charged in port and also via the excess power generated by the engines whilst the ship is underway. The batteries can be used instead of running another engine at peak times where more power is required and are supported by the power management system.

The batteries are charged overnight from the grid, by means of a plug in port. An impressive 700m2 of solar panels is also installed to provide energy for around 50% of the hotel services on the vessel and thus provide some independence from conventional fossil fuels, the overall target being a 25% reduction in usage. The 472 solar panels are located on the wheelhouse (upper most) deck between the two navigation bridges and are directly connected to the switchboard, so they effectively work as another generator. The power that they generate is consumed directly aboard the vessel. The green attributes of this state-of-the-art short haul vessel also extend to the installation of what is known as a thermal water buffer tank, which has a capacity of 80m3 and is filled with fresh water. During the day, a heat recovery system recovers the heat from the engines’ cooling fluid to heat the tank’s contents. During the night, when the Texelstroom is off service, the ship’s passenger saloon and public spaces are heated by the hot water from the buffer tank. This solution replaces a boiler, which would normally heat the ship overnight, so saves fuel. During the summer, energy savings will also be made by ventilating the lower car deck with natural air flow, by opening the upper portion of the doors when under way (weather permitting), obviating the need for forced ventilation. The electric fans will only be switched on when it is necessary for air quality or temperature reasons. Design adaptation to prevailing lateral wind force on the intended route was determined by naval architecture consultancy Van Oossanen through CFD (computational fluid dynamics) analysis of wind behaviour. This promises a reduction of at least 2% in the drag coefficient. Van Oossanen also employed CFD to analyse hull performance, so as to minimise the underwater hull form resistance. Relative to her immediate predecessor, the Texelstroom features smaller funnel casings and slightly lower wheelhouses, and has no atrium on the upper deck, all of which bear upon wind sensitivity and stability factors.

Trail Blazer

Described as an eco-ready trail blazer, the Texelstroom’s layout features a total of seven decks. The ship’s machinery is located on the Tank Top and Tween Deck and above here is the lower vehicle deck. Of the 380 car capacity, 171 can be loaded at this level, along 7 traffic lanes (the outer of which are cars only). The capacity of 34 trucks is also accommodated on the lower deck and, when carrying a full load of freight, a further 52 cars can be stowed on this level. This deck has a deck load of 40 kN/m2, an axle load of 200kN/m and a free height of 4.00m (2.5m in the two outer lanes that are used for cars only). The freight lanes are 3.50m wide and the car lanes are 2.10m wide. Above the main vehicle deck is a full length deck dedicated to the carriage of bicycles. As mentioned earlier, car capacity has been increased on the ferry at upper vehicle deck level by giving her a T-shaped beam section with a cantilevered superstructure. The Texelstroom’s beam is increased here on deck 5 by 3.90m, enabling 14% more cars to be conveyed in two additional lanes, nine in total. This increased beam also benefits the passenger space above. The upper vehicle deck is above the confines of the ferry berths so could be made wider without affecting the existing land based infrastructure. This cars only deck caters for 209 vehicles and has a free height of 3.10m. The deck load is 5.7kN/m2 and the axle load is 17.5kN/m.

Five car lanes are located within the standard dimensions of the ship with two on either side being slewed outboard of the stairway/ancillary room casings. The bow access on the main deck at either end is 7.35m wide and 4.5m high whilst on the upper vehicle deck the access is 7.35m wide and 3.1m high. The embarkation access is offset to starboard, again to maximise vessel dimensions compared to the existing berth configuration, meaning that the Texelstroom will always operate with a dedicated “Texel end” and “Den Helder end.” The two funnels are also on the starboard side, situated on the wheelhouse deck among the solar panels. Even the fire-fighting systems could not escape attention from the designers and innovators. InnoVfoam supplied the foam fire-fighting systems and fire detection systems for the vehicle decks on this technologically advanced ferry. The fibre-optic-based fire detection system in particular is an innovation that has never been used before on a ferry. Because the Texelstroom operates in the Wadden Sea region, a fluorine-free foam extinguishing agent was chosen that minimises the risk of environmental damage. After extensive trials, Lloyd’s Register of Shipping fully approved InnoVfoam’s systems.

The 4,000m2 passenger area is to be found on Deck 6 and around the perimeter of this level at either end is external seating, offering superb views ahead and astern. The key elements for the interior design included transparency as the lounges are created to be very open, symmetric spaces. Another element was the use of environmentally friendly materials and colours that relate to the environment surrounding the Texel service. As a result the primary colours used are green, sand, blue and grey, representing the grass, water, dunes and sky. The large glass panels that look out over the sea are supported by arches based on the outside profile of a pine cone. The large, modern and spacious lounge areas, including the Nordzee Lounge, are pretty much a mirror image of each other, taking up around 65% of each half of this deck. The central area is occupied by the large “Op de Boot” free-flow buffet facility and associated seating/services plus another seating area on the starboard side, punctuated by a large pine tree typical of Texel, which was especially craft-built from treated natural bark, branches and freeze-dried leaves. A crèche area is provided and this has decorative panels with backlit pictures of birds, a seamless resin floor with curved windows to simulate a sandy beach, and shells gathered from the beaches of Texel in the Friesian islands. Indeed, the environment in which the ship operates acted as an inspiration to the designers for every aspect of the interior. Natural and soft lines resemble the tides and waves of the distinctive stretch of water that she plies. The Waddenzee is recognized as a UNESCO World Heritage site and is ecologically very delicate. A further inspiration for her lines was the resident breed of Little Tern. The sheer of the ship is partially based on the form of the wing of this bird, as well as on the distinctive sheer of the first Texelstroom that the company operated in 1966. Lloyd’s Register has classed the Texelstroom with her design being supported by the European Union’s ‘I.Transfer’ Program, which aims to make ferry transport more freely accessible and sustainable, and encourage more people to travel by water. As well as the innovative power arrangements, the design incorporates features important to ferries operating in the area. The vessel is ice class with a strengthened hull in case of winter ice. Additionally, Lloyd’s notation for Passenger and Crew Accommodation Comfort (PCAC) helps ensure a safe and comfortable journey for all.

Towed to Work

The final stages of fitting out for the new ferry were awarded to Damen Shiprepair in Amsterdam (DSAm) and the newbuild was towed there from Santander on 13th April, arriving on 20th April.

She was placed alongside lay-by berth no 2 to permit pressure tests to be carried out to the stainless gas pipes plus steel repairs and additions to the navigation mast were executed. In addition MDO tank 136 was cleaned and the vessel was thus made ready for sea trials and delivery. In addition, DSAm provided berthing for a floating accommodation vessel near the Texelstroom that was used as accommodation for 60 Spanish subcontractor employees. These were provided via LaNaval and tasked with painting the ferry, carrying out final electrical work, laying epoxy floors, fitting furniture and outfitting of the restaurant and kitchen. Upon completion the new vessel was placed under tow again towards her new home on the service to Texel.

Following trials, which commenced on 8th May, La Naval delivered the ship to Koninklijke N.V. Texels Eigen Stoomboot Onderneming (Royal TESO) on Saturday 18th June 2016 at a ceremony in Texel Harbour and a service debut following in time for the 2016 peak season.

With special thanks to Albert Dirk de Jonge, Newbuild Project Manager and the team at TESO for the information, diagrams and images.

Technical Specifications

| Contract Date: | May 2014 |

| Keel Laid: | 30th December 2014 |

| Launched: | 30th July 2015 |

| Delivered: | 18th June 2016 |

| Shipyard: | La Naval |

| Place of build: | Sestao, Bizcaia, Spain |

| Yard No: | 344 |

| Owner: | Texels Eigen Stoomboot Onderneming (TESO), Den Hoorn, The Netherlands |

| Operator: | TESO (Texels Eigen Stoomboot Onderneming) |

| Service: | Den Helder-Island of Texel |

| IMO: | 9741918 |

| Flag: | The Netherlands |

| Port of Registry: | Texel |

| Classification: | +100A1 Passenger/Vehicle Ferry Extended Protected Waters from Texel |

| Ship Type: | Ro-Ro Passenger/Vehicle Ferry |

| Length Overall: | 135.40 metres |

| Length (BP): | 133.38 metres |

| Beam: | (max) 27.90 metres/(hull) 23.00 metres |

| Draught: | (design) 4.050 metres/4.40m (maximum) |

| Hull Depth: | 7.18 metres (to main deck) |

| Gross Tonnage: | 15,483 |

| Net Tonnage: | 5,566 |

| Deadweight: | 1,684 |

| Main Engines: | 2x Anglo Belgian Corporation 12DZC, 2,131kW @750rpm MDO engines (forward engine room) & 2x Anglo Belgian Corporation 12DZD, 2,081kW@1000rpm dual fuel engines CNG/MDO (aft engine room) |

| Dual Fuel: | Compressed Natural Gas (CNG) & Marine Diesel Oil |

| Battery Capacity: | 1.6MWh |

MAIN ENGINE |

|

| Output: | 8,424ekW |

| Solar Power: | 150kWh |

| Propulsion Thrusters: | 4x Rolls Royce US 255P30 FP, each 1800kW Azimuth Thrusters |

| Service Speed: | 10.00 knots (economy speed)/15.40 knots (maximum) |

CAPACITIES |

|

| Passenger Capacity: | 1,750 |

| Upper Vehicle Deck: | 209 cars |

| Lower Vehicle Deck: | 34 Trucks or 171 cars (or 34 trucks & 52 cars) |

| Total Car Capacity: | 380 |

| Lane Width: | 2.10-3.50m |

DECK LOADS |

|

| Upper Vehicle Deck: | 5.7 kN/sqm |

| Lower Vehicle Deck: | 40 kN/sqm |

FREE HEIGHT |

|

| Upper Vehicle Deck: | 3.10m |

| Lower Vehicle Deck: | 4.00m (2.5m in the two outer lanes) |

AXLE LOAD |

|

| Upper Vehicle Deck: | 17.5kN/m |

| Lower Vehicle Deck: | 200kN/m |

|

kN = Kilo Newton |

Comments

Sorry, comments are closed for this item