The multipurpose cargo workhorse is fast emerging as the backbone of the modern day bulk shipping industry, enabling an individual vessel to be adapted to multiple roles and cargoes with ease, thus maximising the revenue earning potential for such a ship through good old fashioned versatility. Every so often a new design comes along that stands out from all the rest and Wagenborg certainly grabbed the shipping world’s attention when their new EasyMax design became a reality.

Triple Easy

The ideologies for this new adaptable carrier were Easy to Build, Easy to Operate and Easy to Load.

Bullet points for such an innovative ship design include optimal loading conditions, economical construction, low fuel consumption, large & varied cargo intake, high manoeuvrability, steady seakeeping, a length-over-all below 150 metres (to avoid the requirement for tugs and to keep port fees low), maximum payload with volume preferred over weight, installed power below the 3,000kW threshold (which would require higher manning levels) and no line of sight restrictions from the bridge. The EasyMax design ticks all of these boxes and is of an open-top multi-purpose ice-classed vessel format. Load capacity is 14,300 tonnes and the hold capacity is an impressive 17,698 cubic metres. The combination of that large load capacity and very low fuel consumption makes this Wagenborg vessel a leader in her segment in terms of sustainability. The contract to build the very first EasyMax ship was awarded to the Royal Niestern Sander Shipyard located in the Northern part of the Netherlands with a direct connection to the North Sea via the port of Delfzijl. A significant area of the Delfzijl harbour accommodates this facility, one of the most modern and versatile shipyards in the Netherlands. The shipbuilding yard is fully equipped for the engineering and construction of ships up to 14,000dwt and has a product history which includes multipurpose dry cargo vessels, IMO 2 tankers, bulkers, container feeder ships, anchor handling tugs, ice breaking support multipurpose vessels, a maintenance support vessel for the offshore industry (Walk-to-Work equipped) plus, most recently, an open-top multi-purpose ice-classed vessel (the EasyMax design). The yard boasts two floating docks for ships up to 200m long/25m beam plus a 600m long quayside. Other activities include Shiprepair and conversions/lengthenings. Delfzijl takes its name from a sluice (zijl) between the Delf and the Ems, which became a fortified settlement in the 16th century. The yard opened in 1901 when shipbuilder Berend Niestern and his sons settled in Delfzijl and started a shipyard where iron ships were built. Twenty years later the brothers Gerhardus and Jacob Sander also began shipbuilding activities in the port. The established Appingedam Shipyard and the Niestern Yard merged in 1970 with the new company being named Appingedam Niestern Delfzijl. Ten years on from this, the facility merged with the Sander yard and became Niestern Sander BV. In May 2001 the Sander shipbuilding and repair company celebrated its centenary. At this time, to acknowledge the many generations of shipbuilders that the Niestern Sander Shipyard represents, the company was also rewarded with the granting of a Royal title in May 2001.

The radically designed newbuild was born into a shipping fleet which, at the time of writing, consisted of 175 vessels in the 1,700dwt-23,000dwt band, not to mention a shipping company that boasts a long history. By way of a precis of Wagenborg’s heritage, Egbert Wagenborg, was born in 1866 and his interest in the maritime world began as a child and at the age of just 10. In 1898 Mr. Wagenborg moved to Nieuweweg in Delfzijl and began running what was by now his two ship fleet under the company name of E. Wagenborg scheepsbevrachter Delfzijl from a café. The company’s early business focussed on the timber trade and involved contracting the unloading of seagoing vessels carrying timber and transporting it to and from timber yards in the North of the Netherlands. By 1901 Egbert Wagenborg had a broad portfolio of activities and was working as a charterer, tradesman and ship owner. In 1903 the company moved to its own office in Waterstraat. By 1921 the cargo and ferry services were expanding, including the undertaking of longer sea voyages. From 1925 the marine engine arrived on on scene with the company’s first motor vessel, the Fivel, being purchased in 1927. In 1948 Wagenborg celebrated its 50th anniversary and in the 1950s the company further raised its profile and also acquired a ship that would be the first in the fleet to carry the name of the founder. The ship names ending in “borg” came onto the scene from 1953 (incorporating river names such as Kroonborg) and fleet modernisation commenced in 1959. That same year the passenger services arm of the company saw an upsurge and the 750 passenger capacity Rottum was launched in 1960. The 1960s saw the fleet grow to 24 vessels including ships at 17,700dwt equipped with 12,000hp engines. From 1966 Wagenborg commenced a programme aimed at lowering the average age of the fleet whilst the towage and passenger sectors were also on the up. A new generation of rectangular hold timber vessels arrived in 1970 in the form of the Scheldeborg. Thirteen “borg” ships were employed in 1974 when the Maasborg was delivered. The Polarborg and Lindeborg arrived in 1982, the haulage industry became part of Wagenborg’s portfolio and, in 1986 the marine services of the Directorate for Public Works and Water Management were acquired. A sizeable newbuild programme was launched in 1990, consisting of four ships of around 3,000dwt with the highest Finnish Ice Class and suitable for transporting high volume goods. The ships were given the names Flinterborg, Balticborg, Eemsborg and Bothniaborg and were followed by the Rijnborg and Scheldeborg in 1991. In 1994 container-feeder vessels were introduced in the form of the Reestborg and Reggeborg, with a capacity of 558 TEU. The haulage sector continued to grow, the tug segment shifted towards towage voyages rather than solely within the port of Delfzijl and in the centenary year of 1998, Wagenborg was awarded the designation “Royal.” What is now the Wagenborg Group of companies continues to flourish and in 2013 the Reestborg was launched. This 14,141gt and 170m long/20.40m beam multi-purpose ship became the biggest ship ever built by Ferus Smit shipyard in Leer and was the first in a series of three vessels featuring the new eco-bow. The offshore sector also gained its first “Walk to Work” enabled ship following an order placed in 2013. As if to underline the importance of the EasyMax class of ship, the premier representative became the third ship to carry the name of Wagenborg’s founder, Egbert Wagenborg.

Going Dutch

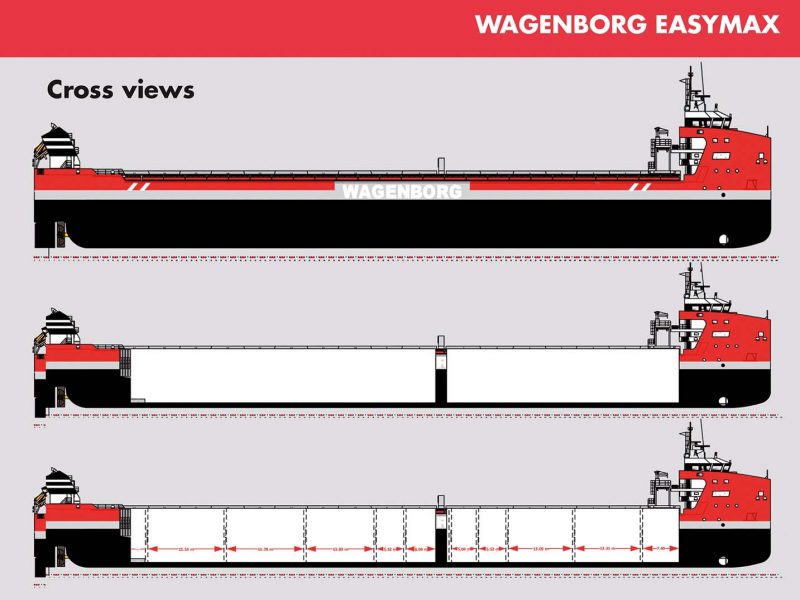

Yard No. 850 began to take shape in December 2015 when her keel was laid at the Royal Niestern Sander Shipyard in Delfzijl. The ship really was home grown as Royal Wagenborg also has its headquarters in Delfzijl, a city with a population of over 25,600 in the province of Groningen in the northeast of the Netherlands. It is therefore no surprise that the vessel embodies a high proportion of Dutch content, underlining the fact that the Netherlands, and the northern provinces in particular, remain firmly committed to national industrial production and therefore retain the associated skill bases. The commissioned newbuild has an overall length of 149.95m, a beam of 15.90m, a design draught of 8.30m and a hull depth of 12.20m. These dimensions mean that the Egbert Wagenborg (iii) is the largest vessel ever built at a yard situated on the landward side of the dikes in the North of the Netherlands. Indeed, the length and beam are the maximum possible for manoeuvrability in the shipyard basin and the breadth is also the maximum for access through the sea lock into Delfzijl’s outer harbour. The vessel was launched sideways, port side first, on 2nd February with fitting out then being completed.

Once in the water, the imposing profile of the Egbert Wagenborg became even more apparent, further enhanced by Wagenborg’s striking livery. The forward bridge and accommodation plus a vertical stem with no rake on the bow make her look rather commanding for a “small” ship. The vessel has such an array of different cargo options, and subsequent draught variations, that a bulbous bow was not deemed efficient across this range. The EasyMax also boasts an exceptionally high length-to-breadth ratio, has a freeboard of 3,515mm, an air draught (in ballast) of 34.23m and a gross tonnage of 8,878gt. The fore-ship section actually echoes that of the 3,696gt/2015 built Kroonborg, a walk-to-work vessel which won the Ship of the Year award in 2015. An extensive model testing programme was undertaken for this newbuild design, particularly to minimise ship motions while maintaining a high efficiency. The aft of the EasyMax was designed by Conoship and was conceived to ensure a good inflow of water towards the upper regions of the propeller duct. The superstructure is located forward so as to maximise the area of the hull envelope available for use for revenue-generating purposes, providing greater hold volume in the aft section and more cargo space on deck. This configuration also reduces the overall tonnage by 30t and enhances loading flexibility in terms of deck cargo and project shipments as line-of-sight from the bridge is not an issue. The bow space is of little use for cargo in general so to place the superstructure here makes perfect sense. The accommodation is also lower than in a conventionally laid out vessel of this type and, as a result, the centre of gravity is lower, improving ship stability and load capacity. Crew comfort aboard the EasyMax is not compromised by the location of the superstructure thanks to the wave-cutting nature of the bow form as it reduces pitch while the greater distancing of navigating and living quarters from the machinery spaces means that the noise level is much lower. The forward mooring deck is also enclosed, affording protection from the elements whilst access to the below deck cargo spaces is positioned midship.

Two box-shaped, flush-sided cargo holds feature in the EasyMax design and account for 13.5m of the 15.9 hull width and provide a depth of 12.1m below the hatch covers. The width of the cargo holds is normally 13.2m on a ship with a beam of 16m. However, because 13.5m would allow extra timber pallets to be carried over the entire length and height of the cargo hold (a 9% increase in capacity) Wagenborg took this option. The open top operation and the narrower wing tanks (by 15cm each) on each side required a very strong hull structure. Because the passageway on deck became prohibitively narrow, the bulwarks were placed on top of the rubrail, rather than on deck. To ensure passage from the accommodation to the lifeboat and the engine room aft, a corridor is provided under the deck from fore to aft. The forward hold is the smaller of the two, being 47.4m long, while the No2 hold is 64.4m in length. The hatchways are closed by pontoon-type covers supplied by the Dutch manufacturer Coops & Nieborg, and are handled by way of a purpose built, low-profile, rail-mounted gantry travelling astride the cargo spaces. When the ship sails in “open top” mode for the transportation of outsized items of freight, including wind energy equipment, the hatch covers are stacked at each end of No.1 hold, at the after end of No.2 hold, or the third option is to leave them ashore altogether.

Another key point of the design is the limited amount of fittings in the hold spaces, due to the absence of ‘tweendecks, beams, securing eyes and container foundations, so as to reduce handling and cleaning time and save expense and weight. However, portable bulkheads that can be placed in different positions across each hold are employed to extend the ship’s trading flexibility, by providing separation between different grades and types of cargo. In addition, the underdeck spaces retain fixed fire protection, dehumidifiers and lighting. The freeboard is high due to the ship’s intended high-volume low-weight cargo and the poop deck is at the same level as the cargo hatch covers. In total, 100 tons of weight has been saved above the vertical centre of gravity, which results in a higher cargo capacity and less requirement for ballast water. The lightship weight is consequently spread evenly over the length, the trim of the vessel is less dependent on the loading condition, and less ballast water is needed for trim correction.

The trades that the Egbert Wagenborg will be engaged in comprise forestry goods (including timber, paper and cellulose), steel products, bulk commodities, breakbulk freight, project shipments and indivisible items such as machinery, industrial plant, wind turbines, and other equipment. With a hull strengthened and fitted to Finnish/Swedish Ice Class 1A requirements, the EasyMax is ideal for year-round Baltic navigation. Royal Wagenborg has also emerged as an important player in transatlantic trade to and from the St. Lawrence River and Great Lakes, another sphere of operation available to the newbuild.

Maximum Economy

With the general arrangement and hull form being highly innovative for this type of ship, the propulsion installation is somewhat conventional. A single 6M32C, 2,999kW/600rpm MaK diesel engine (produced at Caterpillar Motoren’s Rostock factory) running on MDO/HFO is installed.

The 6M32C engine, first introduced in 1994, measures 5,921mm long overall and 4,444mm high. The bore size is 320mm and the stroke length is 480mm. The engine drives a 4.2 metre diameter controllable pitch propeller via Cat Propulsion, geared down to 111rpm, which is mounted in a nozzle to maximise thrust and provide consistently economical fuel consumption at 11.5 knots. A 1,005 kVA shaft generator is connected to the gearbox, providing power for both the onboard services and the bow thruster. The latter is a 750kW Veth unit and behind the propeller is a single large free-hanging Benes spade rudder, which is equipped with an ice knife as the vessel is built under the Finnish/Swedish Ice Class 1A. The ice class specification is also one of the reasons for the fitting of a controllable pitch propeller. LNG propulsion was considered, but costs favoured fuel oil. An exhaust scrubber can be retrofitted should the differential in fuel oil prices warrant this when the global sulphur cap of 0.5% comes in to force during 2020. Likewise no ballast water treatment system is required at present. The fuel tanks are located in the double bottom hull. The EasyMax is equipped with a network on which most systems are connected allowing them to be operated and monitored from several locations on board, such as the 11 spacious and modern cabins (for a crew of 7), offices, mess room and gym. A fast satellite link not only provides onboard TV and internet for the crew, but also provides a shore connection for remote access. The technical department has access to most of the digital readouts aboard the ship and can assist the crew to operate safely and economically through the Remote Maintenance System of JRC.

To provide the optimum working environment for the crew, special attention was paid to ergonomics, safety, technology and layout. Set a little aft of the bow stem, the narrow wheelhouse applies the ergonomic and modular AlphaBridge design concept of Rotterdam-based Alphatron Marine Beheer, and features an outfit of 117cm displays. The four large, bright screens are intended to allow viewing from nearly every angle. The bridge itself affords 360-degree all-round vision whilst the solid state S-band scanner type included in the radar package is claimed to be the smallest worldwide. Another space saving touch worthy of note is that the lifeboat and launching equipment is incorporated into the aft of the funnel housing on the stern.

Award Winning Debut

Upon completion of sea trials, the ship’s naming ceremony took place at the shipyard on 21st April 2017 when, for the third time in 67 years, a vessel of the Wagenborg fleet received the name of the company’s founder. The ship was christened by Ms. Liesbeth van Wessum, wife of Mr. Jan van Nieuwenhuizen, a member of the Board of Directors of Rabobank. After the ceremony the authority of the vessel was transferred to Captain Erik Magel. The ship departed Delfzijl on 30th April for her maiden revenue earning duty to the island of Gotland, Sweden, to load a consignment of limestone from the Nordkalk Storugns quarry for discharge at Kokkola, in Finland.

On 6th November Wagenborg Shipping won the 2017 KVNR Shipping Award with the innovative and sustainable Egbert Wagenborg. The prize was awarded by the Royal Association of Netherlands Shipowners during the Maritime Award Gala, where the pioneering Dutch maritime industry is highlighted. The Shipping Award was for distinctive business management in the area of ship innovation and for social organisational and environmental innovation in maritime shipping.

The EasyMax was described as being designed using the ‘art of omission’. With only essential ship equipment, looking at loading possibilities and placing the accommodation in the bow, a low budget and lightweight class of ship has been created. The EasyMax design plays to Royal Wagenborg’s strengths in the dry cargo and project shipment sectors and already looks set to be a winner.

Comments

Sorry, comments are closed for this item